- Parts Required

-

vectra b rear discs

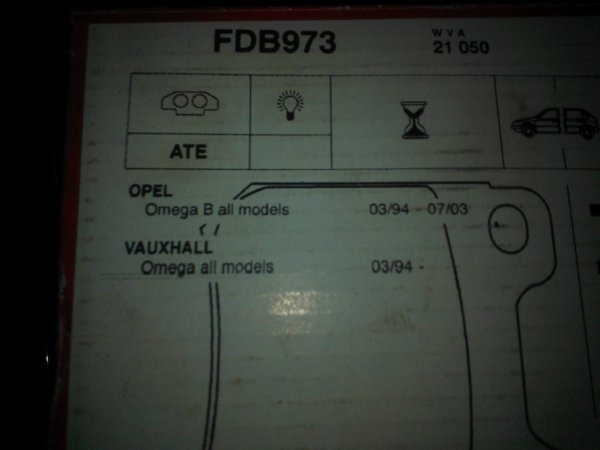

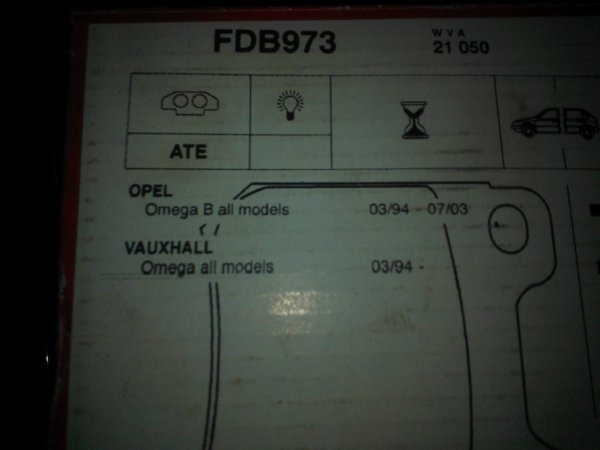

vectra b rear pads 15.7mm

rear pad pin and spring kit

vectra b disc shoes

copper grease

here is a guide to change the rear pads,discs,shoes on a vectra b

park the car on level ground and chock the front wheels

slacken the wheel bolt while the wheel is on the floor

then jack up the car and place the axle stand in a suitable location

then remove the wheel

1st step is to take the Philips screw driver and the hammer

pop the screwdriver in to the screw and hit 2-3 times with the hammer

this step is to check if the screw holding the disc on will come out or if its seized

it will need the head drilling off to remove the disc if it is stuck in

with a hammer and the 3mm punch tap out the pins holding the pads in the calliper

would be better spray them with wd40 before hand i did not have any so went in dry

now the pins are out use the large flat bladed screwdriver to push the pots open on the calliper

just remember to keep and eye on the brake fluid level in the reservoir

sometimes you get some Muppet top the brake fluid up with worn pads and discs so when you push the pots in you get fluid level above the maximum mark

""fluid level should only be at the maximum with new pads and discs all round this way when the fluid level is at minimum you know all your pads and disc require replacing"" thanks to dad for topping up!!

pull out the pads with pliers

there the originals and done alot of miles none of the part can ever be used again there well past it

none of the part can ever be used again there well past it

to remove the calliper use the 19mm spanner and socket to undo the upper and lower holding bolt

there just enough movement in the fixed pipe to move it out the way

time to pop the cover on the hand brake and slacken off the cable

removing the discs will require the use of a hammer and some wiggling it will eventually come off to revel the hand brake shoes

removing the shoes you will need to unhook the upper and lower spring then put some money in the swear box/tin

then there are the spring rivet things holding the shoes in you will need to grip the end push in and twist to get them apart add more money to the swear box as you go

before fitting the new shoes pop a blob of copper grease on each contact point

fit the shoes one at a time i used a set of long nose mole grips to hold the pin still while pushing the spring and washer back on the swear box came handy here to

refit the lower spring

hook in one end the use the long nose mole grips to pull the other end into the hole

on the top side fit the shoe adjuster between the shoes here it is fully retracted

now fit the upper spring same as the lower one

apply a small amount of copper grease to the hub flange

the new disc can now be fitted it will be a little stiff to fit but a good shove once its on squire get it on

refit the holding screw

pop the calliper back in place and bolt it back on FT

take 2 spanners and push the pistons all the way home use one to hold one in while pushing the other in

once you have the calliper setup for the new pads take the box of pads you bought then find out the pads are 17mm and not 15.7mm and dont fit then faff for about an hour go back to the shop and get the right ones

the right ones with new pins and springs

apply a little copper grease to the edges of the pad and fit

copper grease on the end of the new pins

fit the springs

and tap the new pins all the way home till the tip is just showing out the hole

heres the shoe adjustment screw

and here a short txt on how to set-up the hand brake

park the car on level ground and chock the front wheels

slacken the wheel bolt while the wheel is on the floor

then jack up the car and place the axle stand in a suitable location

then remove the wheel

1st step is to take the Philips screw driver and the hammer

pop the screwdriver in to the screw and hit 2-3 times with the hammer

this step is to check if the screw holding the disc on will come out or if its seized

it will need the head drilling off to remove the disc if it is stuck in

with a hammer and the 3mm punch tap out the pins holding the pads in the calliper

would be better spray them with wd40 before hand i did not have any so went in dry

now the pins are out use the large flat bladed screwdriver to push the pots open on the calliper

just remember to keep and eye on the brake fluid level in the reservoir

sometimes you get some Muppet top the brake fluid up with worn pads and discs so when you push the pots in you get fluid level above the maximum mark

""fluid level should only be at the maximum with new pads and discs all round this way when the fluid level is at minimum you know all your pads and disc require replacing"" thanks to dad for topping up!!

pull out the pads with pliers

there the originals and done alot of miles

to remove the calliper use the 19mm spanner and socket to undo the upper and lower holding bolt

there just enough movement in the fixed pipe to move it out the way

time to pop the cover on the hand brake and slacken off the cable

removing the discs will require the use of a hammer and some wiggling it will eventually come off to revel the hand brake shoes

removing the shoes you will need to unhook the upper and lower spring then put some money in the swear box/tin

then there are the spring rivet things holding the shoes in you will need to grip the end push in and twist to get them apart add more money to the swear box as you go

before fitting the new shoes pop a blob of copper grease on each contact point

fit the shoes one at a time i used a set of long nose mole grips to hold the pin still while pushing the spring and washer back on the swear box came handy here to

refit the lower spring

hook in one end the use the long nose mole grips to pull the other end into the hole

on the top side fit the shoe adjuster between the shoes here it is fully retracted

now fit the upper spring same as the lower one

apply a small amount of copper grease to the hub flange

the new disc can now be fitted it will be a little stiff to fit but a good shove once its on squire get it on

refit the holding screw

pop the calliper back in place and bolt it back on FT

take 2 spanners and push the pistons all the way home use one to hold one in while pushing the other in

once you have the calliper setup for the new pads take the box of pads you bought then find out the pads are 17mm and not 15.7mm and dont fit then faff for about an hour go back to the shop and get the right ones

the right ones with new pins and springs

apply a little copper grease to the edges of the pad and fit

copper grease on the end of the new pins

fit the springs

and tap the new pins all the way home till the tip is just showing out the hole

heres the shoe adjustment screw

and here a short txt on how to set-up the hand brake